If there was an industry that felt the impact of the 2020 COVID-19 pandemic, it was the manufacturing sector.

The industry had already spent much of the last few years attempting to shift its structure and response to meet increased global competition – while simultaneously working with increased global tariffs from the Trump administration. These changes, along with the rise in automation and intelligent technology, forced manufacturing to keep moving at a sprint to keep up with consumer expectations.

Then came the arrival of a border-closing global pandemic. As COVID-19 raged across the world, the manufacturing industry felt a one-two-three punch of disruptions that left many wondering if the industry could recover. Supply chains buckled under the strain of meeting panicked demand, and production lines halted as workers became sick themselves.

Fortunately, the future remains bright for manufacturing. The fact that the manufacturing sector is a relatively resilient and essential industry – as well as a fast rebounding economy – are good omens for the new year.

However, above all other external factors, manufacturing will be most impacted by a single mega-trend: data-driven revolution. As the world continues to move in an increasingly digital-first direction, consumers’ and companies’ interaction with manufacturers is changing rapidly. The addition of smart tech, data-driven solutions, and global connectivity is altering how the industry operates – and 2021 will see that evolution only increase in speed.

In this article, we will break down six of the major trends that will impact manufacturing in 2021 – both as a response to the 2020 pandemic and in preparation for the future.

1. Manufacturing-Based Machine Learning Technology Will Grow & Expand

2021 will see a continuation of the explosive growth in automation in manufacturing.

These powerful technologies will be driven by innovations in both artificial intelligence (AI) and the fast-growing field of automation programming known as machine learning (ML).

Rather than depend on a limited human workforce alone, manufacturing will continue to adopt ML-led automation across the industry.

Robotics: The International Federation of Robotics reports that as of late 2020, there are 2.7 million industrial robots operating in warehouses and factories around the globe. This is a growth of 85% in just five years, and the coronavirus pandemic looks to only put a small dent in the rate of growth.

Asia leads the way in automated manufacturing, with North American and Europe fast behind.

5G Implementation: 2021 will likely see continued adoption of 5G technology across the world. While the adoption of 5G hasn’t been without controversy, this has remained mostly confined to the public rather than the private sectors. In fact, reporting firm McKinsey forecasts that nearly a quarter of the globe will be plugged into 5G coverage by the end of the decade – with manufacturing seeing a boost up to $650 billion GDP due to faster wireless technology.

Digital Twin Technologies: Another innovation led by machine learning is the availability of digital twins. These technologies allow for manufacturers to double their output of products before the launch of the entire production process – which can help reduce costs across the board and streamline manufacturing for all industries.

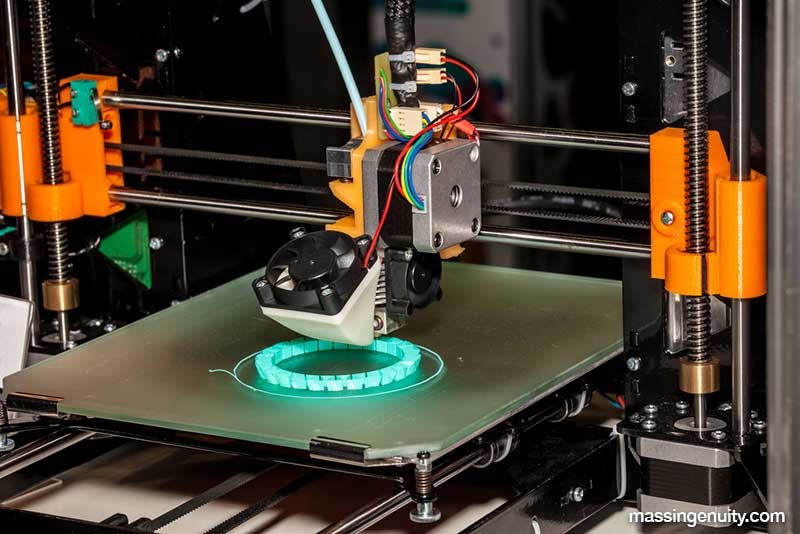

3D Printing: While 3D printing was already becoming a part of the manufacturing process in many fields, continued advances in the capabilities of 3D printing and the reduction in operating costs of printers will see their popularity continue to climb.

While these are but a few examples of ML-led technology advancements, it is clear that automation will continue becoming a norm in manufacturing, especially as firms look for ways to reduce overhead costs and catch up from 2020 losses.

2. IoT Digital Connectivity Will Drastically Increase

The Internet of Things (IoT) has radically changed how manufacturers navigate both their production and distribution processes.

Unfortunately, for all the advances in IoT systems for manufacturing, the global pandemic was far too disruptive for most supply lines to maintain the status quo.

However, the pandemic did act as a “global wakeup call” for manufacturers who were not yet taking advantage of the streamlined potential of IoT connectivity. Tech firm Accenture reported that nearly 94% of all Fortune 1000 businesses saw a drastic impact on their supply chains due to COVID-19.

Those disruptions lead to angry consumers, which then moves backward from the company to the manufacturer. As a result, companies will demand that manufacturers adopt IoT technology that allows for fast reporting and response across their systems should another black swan event occur.

In 2021, modern manufacturers will use IoT solutions to increase their overall connectivity in nearly all aspects of their operations – from inventory management and equipment maintenance to HR and customer service. Breaking down organizational silos will further allow manufacturers to increase their speed and reduce friction from disruptions.

3. The Adoption of Predictive Maintenance Will Become Necessary

Similar to the implementation of IoT solutions across manufacturing systems, the industry will also see a drastic rise in predictive maintenance technology in 2021.

Predictive maintenance utilizes machine learning and artificial intelligence to create predictive models that allow nearly every piece of equipment used in the manufacturing process to be monitored in real-time.

Rather than depend on employee-led inspections, predictive maintenance will use innovative sensors and IoT technology to alert manufacturers of equipment issues and failures far before becoming a costly issue. Predictive maintenance solutions can increase the lifetime value of assets – which can reduce costs across the board.

4. The Supply Chain Will Be Strengthened With Data

COVID-19 disrupted global supply chains unlike any other event in modern history. As manufacturers emerge from the dust and debris of 2020, they will be looking for ways to prevent massive supply chain disruptions in the future.

The answer may not be in overhauling the supply chain system but strengthening it with data-driven solutions. With innovations in ML and automation, manufacturers will increase their ability to monitor, react, and supplement any supply chain disruptions quickly and with less downtime.

Additionally, 3D printing and robotics will help increase the ability for multi-sourcing and allow for production to occur in more places. This can help relieve the strain on supply lines when disruptions inevitably occur. With the addition of real-time data analytics, manufacturers can better monitor and optimize underperforming supply chains to increase their overall efficiency.

5. Manufacturing Will Continue To Become Agile & Lean

No longer will lean operation philosophies be relegated to the white-collar world. In 2021, manufacturing will continue to push toward a more agile and lean operation across the industry.

In the same way that companies can benefit from increased productivity and closer teamwork, manufacturing will see a boost from team-focused culture upgrades that can ultimately decrease the amount of wasted time, effort, and materials.

6. Employee Health & Wellness Will Rise In Importance

Why did 2020 see such a massive disruption from manufacturing? While it is easy to offer blanket blame to COVID-19, part of the issue was the high rates of infection and sickness in the teams that work in the manufacturing sector.

Working in close quarters for long hours, many employees in manufacturing roles became sick with COVID-19, and the infection spread across the workforce in individual warehouses and production floors. In many cases, the entire company had to shut down for a time due to a lack of workers.

In 2021, a focus on employee health and wellness will continue to grow as manufacturing continues to depend on the human workforce. As the manufacturing industry still holds one of the highest rates of on-the-job injuries, a move toward a lean and higher-performing workforce will require the use of intelligent technology and innovative communication systems to ensure that all team members remain healthy and well.

2021 Manufacturing At A Glance: Recovery & Revitalization

Much of the 2021 trends in manufacturing center around the concept of recovering from the impacts of the COVID-19 pandemic on the workforce and supply chains.

However, the problems that emerged across 2020 were not due to the coronavirus alone but were issues that rested under the system’s surface for many years. The pandemic simply brought these issues to the surface in startling ways.

However, recovery cannot happen without revitalization. For manufacturers to recover and move forward with confidence, they will need to continue adopting technological solutions that will allow them to avoid the costly impacts of disruptions.

The addition of ML and AI technology and the implementation of IoT solutions will help manufacturers increase their effectiveness and output while lessening the strain on their workforce. By assisting teams in working smarter rather than harder, manufacturers will be able to recoup losses in 2021 and move ahead boldly to tackle the next disruption.

If you are ready to learn how to manage your data and boost your company’s performance in all areas, contact Mass Ingenuity. Our team of data experts has years of experience helping organizations and companies use data to increase their effectiveness. With the right data solution and tools at your disposal, you can improve your potential and prepare to step into 2021 as a significant competitor with manufacturing operations.